Soil Permeability Testing

The permeability test is the measure of the flow of a liquid through a soil sample.

A soil consists of solid particles with void spaces in between. Generally a granular material (sands & gavels) has larger void spaces allowing higher flow, and a fine grained soil (silts and clays) has smaller voids, limiting flow.

The permeability of a soil is reported in metres per second (m/s), usually in engineering notation due to the small magnitude of the number e.g.: 1E-9 m/s.

What is a permeability test?

Laboratory Permeability testing can be undertaken using 3 different procedures in accordance with Australian Standards AS1289.

Falling Head and Constant Head use a flexible wall permeameter (Triaxial). The Constant Head method is best suited for gravels and sands, the Falling Head method for mixtures of sands/silts /clays, and the Triaxial method for high plasticity/ low permeability Clays.

Typical permeability results for Gravels and sands range up to 1E-5 m/s, silty sands, sand clay mixtures 1E-6 to 1E-8m/s, and clays less than 1E-9m/s.

The Constant Head and Falling Head tests are usually undertaken on samples remoulded in the laboratory to specific moisture and density conditions. The Triaxial permeability can be undertaken on remoulded or undisturbed samples.

Permeability testing is used for projects requiring clay liners including dams, waste landfills, tailings storage, retention/detention basins. Or capping layers for waste landfill, tailings dams.

The permeability of a soil could vary based on the remoulding density and moisture condition of the sample.

Difference between constant head and falling head permeability tests

The Constant Head method is undertaken with a fixed hydraulic gradient, a reservoir above the sample has the water level maintained at a constant level, while the water is allowed to flow through the soil sample and the outflow is collected. This is measured at regular time intervals.

The Falling Head method is undertaken with a falling hydraulic gradient, a clear standpipe above the sample is filled with water, as the water flows through the sample, the water level in the standpipe drops and the change in water level is monitored over time.

The Triaxial permeability method is undertaken with a constant hydraulic gradient, using automated pressure controllers to maintain confining pressure, inlet pressure and outlet pressure and to measure the volume change.

Constant Head Permeability Test (AS1289.6.7.1)

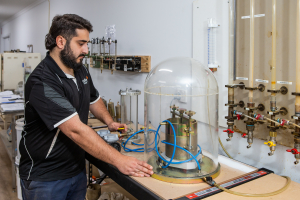

Samples are prepared and remoulded in a rigid cylindrical cell. Prior to percolation measurements, the sample is saturated inside a large sealed chamber, using a vacuum pump. Water flow is monitored to determine if the Constant Head method is applicable. If saturation cannot be achieved after 24 hours, the test should be performed in accordance with AS1289.6.7.3 (Triaxial Permeability).

The hydraulic head (constant head) is the difference in the height from the top of the water level in the reservoir tank to the bottom of the overflow outlet on the permeability cell. The hydraulic head is determined before the test; for loose soils a low gradient is used, for dense or fine grained soils a higher gradient is needed. Water is percolated through the sample and collected, and measured at suitable intervals until the rate of flow is consistent.

If the volume of water collected in 24 hours is less than 150ml this method is not applicable and the Falling Head method should be used.

Falling Head Permeability Test (AS1289.6.7.2)

Samples are prepared and remoulded in a rigid cylindrical cell. Prior to percolation measurements, the sample is saturated inside a large sealed chamber, using a vacuum pump. Water flow is monitored to determine if the Falling Head method is applicable. If saturation cannot be achieved after 24 hours, the test should be performed in accordance with AS1289.6.7.3 (Triaxial Permeability).

Samples are prepared and remoulded in a rigid cylindrical cell. Prior to percolation measurements, the sample is saturated inside a large sealed chamber, using a vacuum pump. Water flow is monitored to determine if the Falling Head method is applicable. If saturation cannot be achieved after 24 hours, the test should be performed in accordance with AS1289.6.7.3 (Triaxial Permeability).

Water is percolated through the sample and water level in the standpipe is monitored at regular intervals over at least 3 days until the rate of flow is consistent.

For samples having permeabilities >E-7 m/s excessive flow may result and the Constant Head method may be more suitable.

For samples with permeability

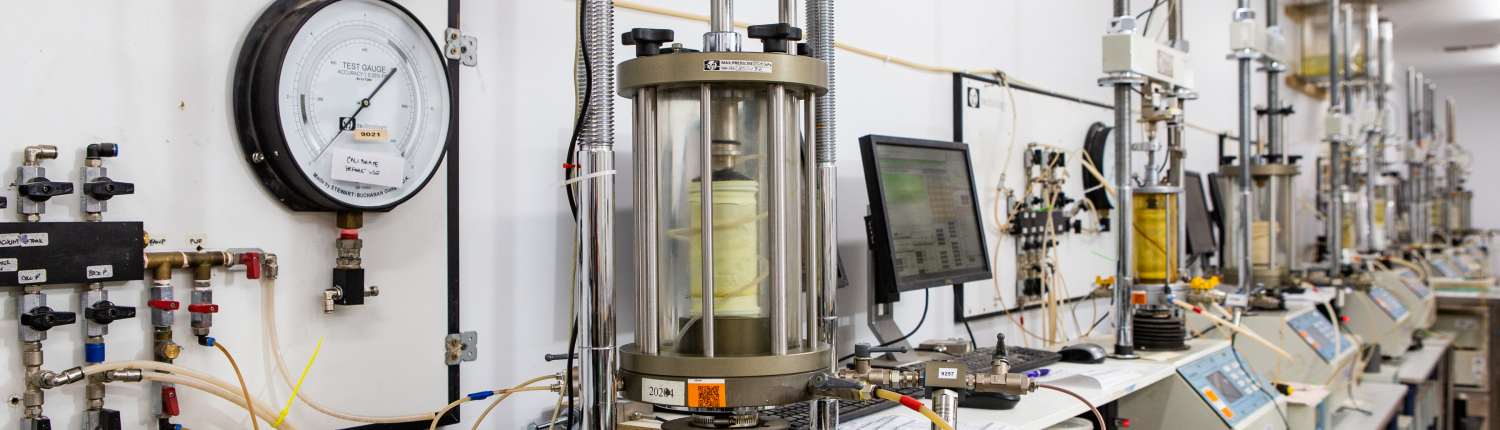

Triaxial Permeability Test AS1289.6.7.3)

Remoulded samples are prepared and remoulded in a split cylinder which can be removed from the sample before testing. Undisturbed samples are extruded from an undisturbed sampling tube, and trimmed to size. The sample is placed in a triaxial cell and encased in a seamless rubber membrane (flexible wall). The Triaxial cell is filled with water.

The base of the cell and the top cap on the sample both have ports that are connected to separate pressure units. The water in the Triaxial cell is also pressurised. The sample is saturated using back pressure saturation. Following saturation the sample is consolidated to the nominated effective stress pressures.

Percolation of the specimen is undertaken by slightly increasing the pressure at one end of the sample and slightly decreasing the pressure at the other end. Volume change at each end is monitored until the rate of flow is consistent.

Do you have a project that requires Permeability Testing?

For more information about our permeability testing services contact our friendly team here or to request a quote for your next project that requires permeability testing, please complete our Request a Quote form here.